It's been a while since the 3D printing technology arrived on the scene, and now Ford has joined the fray. Why not? Everyone seems to be doing it and is because this technology holds some serious potential.

Ford, one of the oldest and the largest automobile manufacturers in the world is known for experimenting with the new and the innovative to solve old and common problems has now turned its attention to 3D printing. As if they did not push the envelope enough with their aluminum frame!

Test Drive

https://en.wikipedia.org/wiki/3DBenchy

The work has already begun, and a company spokesperson has said that Ford is currently busy testing a large scale 3D printing facility that will allow buyers and drivers to customize their cars in real time. The spokesperson further says that the technology could prove to be a "breakthrough for vehicle manufacturing".

Some of the benefits that we could think of off the top of our minds are cost cutting, better efficiency, faster delivery, and ability to test new prototypes faster and in a better environment. Any one of those reasons are good enough for most people and businesses.

This will also prove to be a boon for cars that are not manufactured on a commercial level like race cars and limited edition cars. As the volume is so low, it becomes difficult to keep costs in check, subsequently resulting in expensive spare parts. 3D printing is all set to solve these issues and much more in the coming years.

This means there will be even more types of cars on the road. They say your car symbolizes your personality. Well, with this type of customization, this notion will be even more poignant.

On-demand

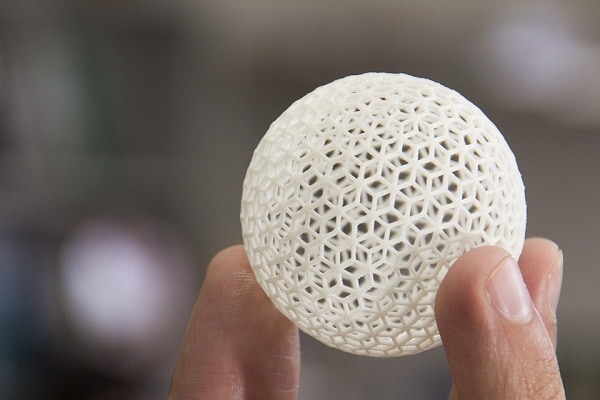

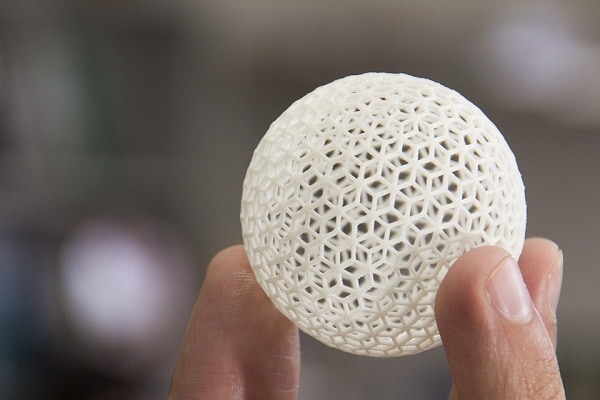

http://maxpixel.freegreatpicture.com/Design-Ball-3d-Printing-597523

It seems that Ford is the first company to adopt 3D printing technology on a commercial level. The results are yet to be seen and we are not sure how Ford plans to deliver it. Maybe each dealer will be sent a customized 3D printing machine by Ford that will allow customers and buyers to choose from a wide array of designs and get accessories and parts in real time? It is a possibility and we are waiting for Ford to confirm.

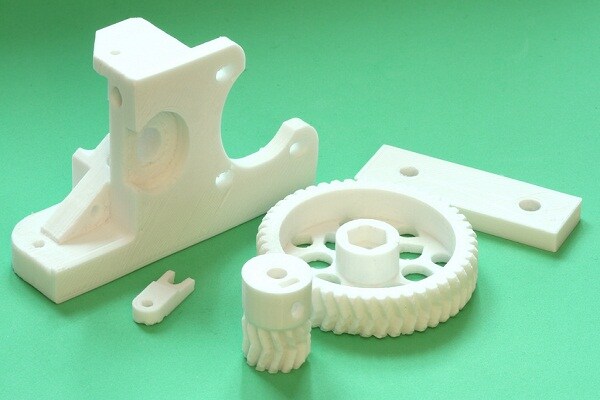

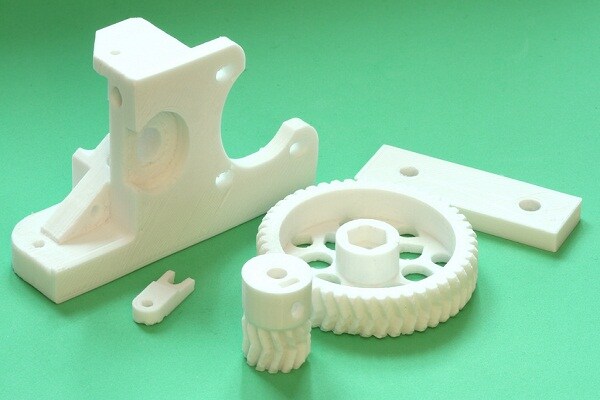

This will also allow Ford to easily test new designs and spare parts. 3D printing process largely uses plastic (study and strong) which means the parts are going to be significantly lighter. This will not only reduce the weight of the car, but also improve its fuel efficiency and performance.

But perhaps a customer could order a special car directly from Ford, its website, for example, and Ford uses its own 3D printer to print out the vehicle and they deliver it to your home.

The specific model that Ford is using for test pilot is Infinite Build 3D Printer manufactured by Stratasys, a Minnesota based 3D printing company that specializes in this technology.

Industry Growth

https://www.flickr.com/photos/acraigie/7168232293

Several tech pundits are now betting on 3D printing technology which is all set to become a $28.9 billion industry by the end of the year 2020. The industry is currently pegged at $13.2 billion. The research was conducted and the report was published by IDC. This includes the printers itself, accessories, and raw materials that are used in the manufacturing process.

The process is fairly simple to understand if not as easy to implement. The designs are created and then sent from the main computer to the printer. The printer will then begin work by creating one layer of the object in question using the raw material at a time.

If more raw materials is needed, there is a robotic arm that will place the required material so that printing can be continued. Ford says that the machine can continue to work for several days at a stretch without any or much human interference.

While other automobile companies have announced their plans on using 3D printing technology to manufacture spare parts in the past, Ford is currently the only one that is going down this road. Not surprising Ford is first!